Peugeot 308: Removing - refitting : Traction battery cooling circuit electric coolant pump

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

1. Tooling

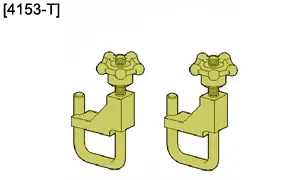

| Tool | Reference | Description |

| [4153-T] (*) | Hose clamp |

| (*) Use standard workshop equipment if the special tool is not available | ||

2. Preliminary operations

Place the vehicle on a 2-post lift.

CAUTION : Perform the operations that are required before disconnecting the ancillaries batteries

.

.

Disconnect the ancillaries batteries

.

.

Remove the under-engine protector.

3. Removing

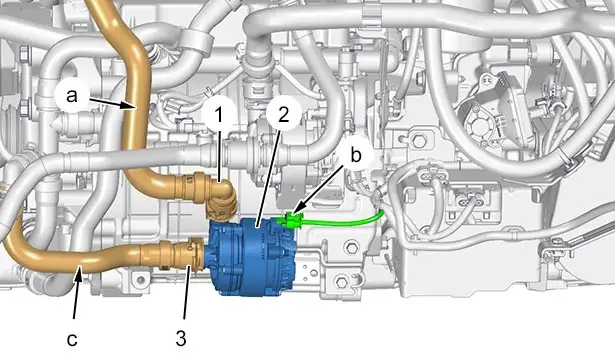

Disconnect the traction battery cooling circuit electric coolant pump (2) connector (at "b").

Position the tools [4153-T] on pipes (1) and (3) of the traction battery cooling circuit (at "a" and "c").

Uncouple and move aside traction battery cooling circuit pipes (1) and (3).

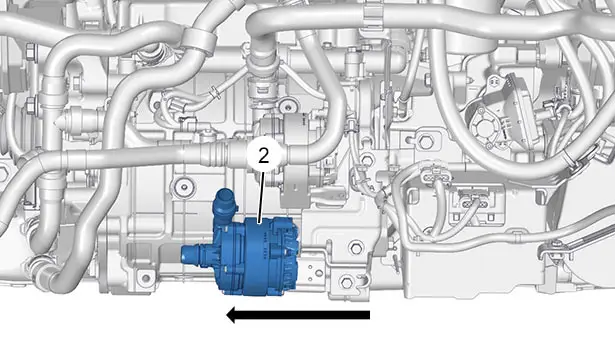

Remove the traction battery cooling circuit electric coolant pump (2) (In the direction of the arrow ).

4. Refitting

Refit the traction battery cooling circuit electric coolant pump (2).

Couple the traction battery cooling circuit pipes (1), (3).

Remove the tools [4153-T] (at "a" and "c").

Connect the traction battery cooling circuit electric coolant pump (2) connector (at "b").

5. Additional operations

Refit :

- The under-engine protector

- The vehicle to its wheels

CAUTION : Perform the operations that are required after reconnecting the ancillaries batteries

.

.

Reconnect the ancillaries batteries

.

.

Fill the expansion tank with coolant until level with the cap.

Degas the electric drive train cooling circuit

.

.

Check the sealing of the electric drive train cooling circuit.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image