Peugeot 308: Organisation bulletin : Commercial launch of the double hybrid clutch-piloted manual gearbox (e-DCT)

This bulletin presents all the technical information required by authorised repairers and distributors of new vehicle and replacement parts for the launch of the new manual gearboxes in (e-DCT) versions that are piloted by double hybrid clutch 2 : MHEV and PHEV.

This bulletin must be presented and distributed in each dealership of the network by each department manager.

New vehicle sales : The sales manager must present this bulletin to all new vehicle sales staff and give them a copy.

Service : Service managers must present this bulletin to all aftersales service staff and give them copies.

Replacement parts activity : The parts manager must present this bulletin to all parts staff and give them a copy.

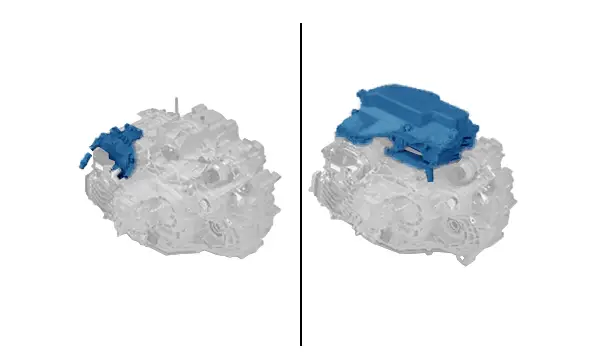

Main information and key points in the bulletin : The hybrid double-clutch piloted manual gearbox (e-DCT).

To be noted in particular :

- The hybrid double-clutch piloted manual gearbox (e-DCT) is available in 2 versions : A version for models MHEV equipped with a 48 volt electric drive machine, A version for models PHEV equipped with a 320 volt electric drive machine

- The seventh ratio was deactivated by software in the 2 versions

- Specific oil which cannot be mixed with any other oil

- 100 000-mile maintenance

1. Product description

The double hybrid clutch-piloted manual gearbox (e-DCT) is a new generation of double clutch gearbox with integrated electric drive machine.

The hybrid double-clutch piloted manual gearbox (e-DCT) :

- Equips the vehicles on all markets in which STELLANTIS operates

- Uses a specific new grade of oil that is different from the kind used on other gearboxes

- Just one maintenance schedule of 100 000 km

- To reduce fuel consumption

The double hybrid clutch-piloted manual gearbox (e-DCT) equips the engine families EB and EP.

This gearbox is designed for front-wheel drive vehicles with a transversely mounted double hybrid clutch-piloted manual gearbox P2 powered by a combustion engine. Rear-wheel drive can be provided by a rear electric drive machine and independent reduction gear P4 e- mounted on the rear axle to be combined with an integral transmission architecture.

2. Technical data

| (e-DCT)-type hybrid double-clutch piloted manual gearbox (MHEV vehicles) | (e-DCT)-type hybrid double-clutch piloted manual gearbox (PHEV vehicle) | |

| Type of gearbox | Double clutch with integrated electric motor | Double clutch with integrated electric motor |

| Number of gears | 6 | 6 |

| Maximum torque ( Nm) | 350 | 350 |

| weight ( kg) | 95 (With oil) | 95 (With oil) |

| Associated engines | EB | EP |

3. Driveshaft - Configuration - Fitting - Fitting

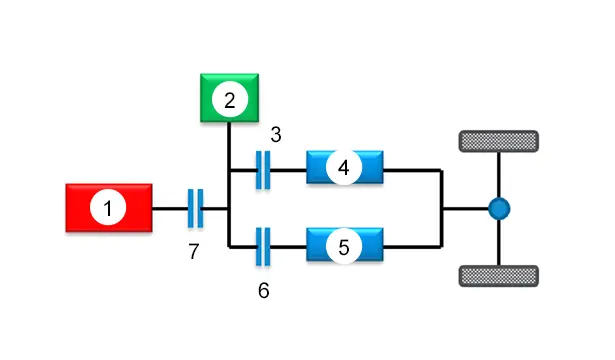

General overview of the adopted topology :

- (1) Internal combustion engine

- (2) Electric drive machine integrated in the double hybrid clutch-piloted manual gearbox (e-DCT)

- (3) "C2" clutch

- (4) Gears 2, 4, 6, "R"

- (5) Gears 1, 3, 5

- (6) "C1" clutch

- (7) Separating clutch "C0"

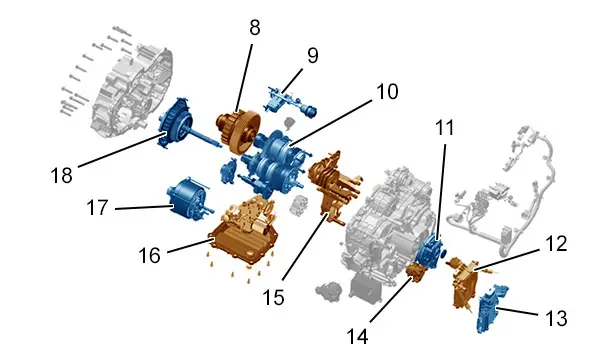

Exploded view :

- (8) differential

- (9) Park finger locking solenoid (Electrohydraulic actuation, universal conformity)

- (10) Input and output shafts on the double hybrid clutch-piloted manual gearbox (e-DCT)

- (11) "C1" clutch

- (12) Electric drive machine inverter

- (13) Hybrid double-clutch piloted manual gearbox ECU

- (14) Clutch cooling pump

- (15) Gear change mechanism

- (16) Oil filter

- (17) Electric drive machine integrated in the double hybrid clutch-piloted manual gearbox (e-DCT)

- (18) Separating clutch "C0" and clutch "C2"

4. Final drive

4.1. Presentation of the (e-DCT) system

The double hybrid clutch-piloted manual gearbox (e-DCT) has a fixed number of gear ratios and ratio changes are made from one clutch to another, facilitating very smooth transitions without any interruption in torque.

The driving experience is similar to when driving with a conventional automatic gearbox (In auto mode, changes in gear ratio without driver intervention and without interruption in torque).

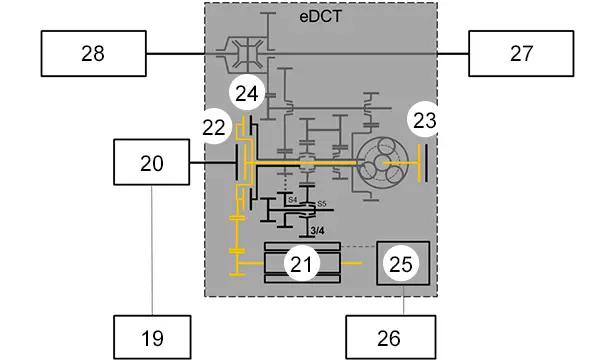

4.2. Hybrid topology

(19) Starter.

(20) Internal combustion engine .

(21) Electric drive machine.

(22) Separating clutch "C0".

(23) "C1" clutch.

(24) "C2" clutch.

(25) Hybrid double-clutch piloted manual gearbox ECU.

(26) Traction battery.

(27) Right-hand wheel.

(28) Left-hand wheel.

DT2 is configured like hybrid topology P2. A 3-phase synchronous eccentric electric motor with permanent magnets (electric drive machine) is connected to the gearbox input shaft between the separating clutch "C0" and clutches "C1" and "C2".

5. Hydraulic system

To function correctly, the gearbox must receive a continuous supply of pressurized oil at a sufficient flow rate to enable the clutches and solenoid valve on the locking parking finger to operate.

Lubrication of internal components and internal convection cooling transfers the heat dissipated from the clutch friction surfaces and the engine ignition coils.

The hydraulic supply circuit comprises :

- An electric oil pump for actuation

- An electric oil pump for cooling

- An oil filter for the hybrid double clutch-piloted manual gearbox

- An oil filter on the hydraulic block with a pre-filled volume of gearbox oil (Hybrid double-clutch piloted manual gearbox)

- A gearbox oil cooler

The maximum pressure needed in the gearbox is approximately 18 bar.

The oil pumps are powered by electrical current to enable the gearbox to function while the engine is switched off, necessary in hybrid vehicles.

The use of 2 independent electric oil pumps enables actuation and cooling to be performed on demand.

Stopping the electric oil pump when power is not needed reduces the average level of electrical power consumption.

An oil filter on the hybrid double clutch-piloted gearbox (e-DCT), a hydraulic block oil filter (hybrid double clutch-piloted manual gearbox) and a magnet installed in the oil reservoir are the components of a filtration system that enables oil to be kept clean throughout its service life by capturing pollutant particles that come from the normal wear of internal elements.

Gearbox oil cooler :

- Extracts the heat coming from the gearbox (or adds heat to the gearbox) to maintain the temperature of the oil reservoir during the various phases of operation

- This is linked to the engine cooling circuit

6. Park finger locking solenoid

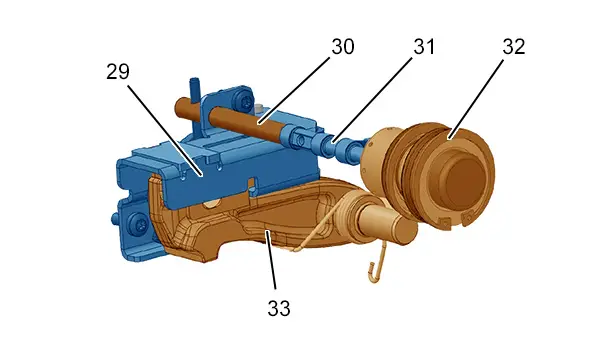

(29) Arming mechanism .

(30) Actuator rod .

(31) The parking finger locking pin .

(32) Parking finger locking piston .

(33) Parking finger .

The park finger locking unit is: :

- Actuated electro-hydraulically by the pressure of the actuator pump

- Armed when not in an excited state

Whenever the locking piston on the parking finger is pressurised (whenever the actuator pump is operating), the arming spring retracts the actuator pin and disarms the parking finger.

Whenever the locking piston on the parking finger is depressurised (whenever the actuator pump is stopped), the arming spring pushes back the actuator pin and arms the parking finger.

A sensor measures the position of the actuator pin, i.e. the locking status of the parking finger(armed or disarmed).

The locking solenoid on the parking finger can block the movement of the pin, when armed or when in disarmed position, to act as a maintenance/neutralisation unit for specific types of operation.

| Case of use | Description |

| Normal operation | Arming and disarming when requested by the driver (gear change lever), by checking the hydraulic pressure |

| Mode "drive-through carwash" mode | Keeping the parking finger locking unit in a disarmed state when requested by the driverSame strategy as for ATx8 |

| Cancellation by diagnostic tool DIAGBOX | Keeping the parking finger locking unit in a disarmed state when requested by the CAN network while the engine is not running |

7. Training for the aftersales activity

7.1. Distance learning modules

Distance learning available on the brand network training website (TG504153V01 - Light electric/hybrid vehicle (MHEV P2) - technical training).

7.2. Attended training courses

A presentation on the hybrid double clutch-piloted manual gearbox (e-DCT) will take place during classroom training when the P8 vehicle is launched.

7.3. Hand-down kit

No dissemination kit is provided.

8. Aftersales documentation

The technical documentation for the hybrid double clutch-piloted manual gearbox (e-DCT) can be consulted on the documentation portal of the manufacturer’s after-sales department.

9. Diagnosis

Diagnostics on the hybrid double clutch-piloted manual gearbox (e-DCT) can only be performed using the DIAGBOX diagnostic tool.

10. Maintenance

Just one single maintenance interval of 100 000 throughout the entire service life.

11. Indicator plate

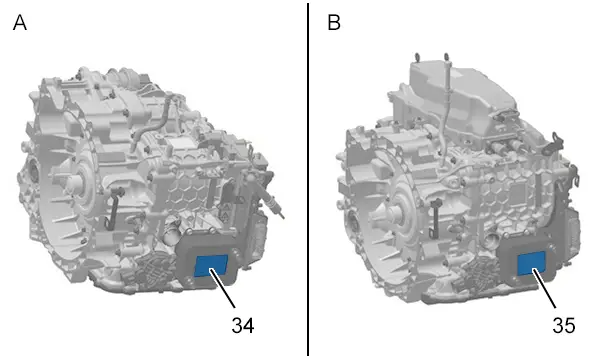

"A" MHEV vehicles.

(34) Indicator plate MHEV.

"B" PHEV 1 vehicles .

(35) Indicator plate PHEV.

| Location | Description of contents | code | Significance of the code |

| Upper section | Matrix code 2D and code that the user can read | AA BB XX YYYYYYY | AA : Type of product = gearbox : 20BB : Production line = Metz : F9XX différent for MHEV / PHEVRatio MHEV D2 A : AYRatio MHEV D2 C : AZRatio MHEV D2 E : A1Ratio PHEV D A : ALRatio PHEV D C : AMRatio PHEV D E : ANYYYYYYY : 0000001-9999999 number |

| Lower section | Barcode 1D and code that can be read by the user | AA BB XX YYYYYYY | AA : Type of product = gearbox : 20BB : Production line = Metz : F9XX différent for MHEV / PHEVRatio MHEV D2 A : AYRatio MHEV D2 C : AZRatio MHEV D2 E : A1Ratio PHEV D A : ALRatio PHEV D C : AMRatio PHEV D E : ANYYYYYYY : 0000001-9999999 number |

12. Towing

Refer to the "Technical note: towing" method available on the manufacturer’s aftersales documentation portal.

13. Warranty

No notable special feature.

14. Recall campaigns

No notable special feature.

15. Reporting of information

Refer to the document "Organisation bulletin: feedback to customers" for the vehicle.

Manufacturer’s Aftersales documentation portal : "DOCUMENTATION" tab ↦Vehicle / General ↦Repair procedures ↦Data - Identifications.

16. Technical assistance

The "Dealer Issue Detection Assistance" (DID-A) is used to contact technical assistance.

Observe the DID standards (Manufacturer’s Aftersales documentation portal : "Incidents-Assistance" tab ↦DID practical information ↦DID standards) :

- Relevance standard

- Quality standard

N.B. : Refer to the organisation bulletin which covers this subject.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image