Peugeot 308: Organisation bulletin : Commercial launch of the naturally aspirated EB2 engine (EB2 FA) - Euro 6.2 emission control standard

This bulletin presents all the technical information required by authorised repairers and new vehicle and replacement parts distributors for the launch of the naturally aspirated EB2 engine that complies with the EURO 6.2 (EURO 6.c and EURO 6.d TEMP) emission control standard for private vehicles.

This bulletin must be presented and distributed in each dealership of the network by each department manager :

- New vehicle sales : The sales manager must present this bulletin to all new vehicle sales staff and give them a copy

- Service : The service manager must present this bulletin to all service staff and give them a copy

- Replacement parts activity : The parts manager must present this bulletin to all parts staff and give them a copy

Main information and key points in the bulletin : To be noted in particular.

CAUTION : Prerequisite : Refer to the "Commercial launch of the EB0, EB2, EB2M engines"; bulletin available on the manufacturer’s aftersales documentation portal.

CAUTION : Prerequisite : Refer to the "Commercial launch of petrol engines that comply with the EURO 6.2 emission control standard" bulletin, available on the manufacturer’s aftersales documentation portal.

CAUTION : Prohibition of the use of additives in the engine oil, and only the "UNIK" and "UNIK+" fuel additives for petrol engines are compatible with EB engines.

The engine family comprises 3 naturally aspirated engines :

- EB2 FA

- EB2 FAd : The engine software-reduced version

- EB2 FAM : Non-Europe world version that complies with the EURO 6.1 emission control standard (EURO 6.b) (Release during 2019)

N.B. : The 208 (A9) is the launch vehicle of this engine (October 2017).

N.B. : The C3 Aircross (A88) is the launch vehicle of this engine (April 2018).

Data :

- Production : Trémery manufacturing and assembly plant

- The best inter-service compromise is obtained by coupling the EB2 FA engine with the MA5 manual gearbox (Only)

- Engine structure EB : 3 cylinders

- Reduction of the timing belt replacement interval

- Removal of the balancing shaft on naturally aspirated EB2 engines

- Asymmetrical crankshaft pulley

- Engine management ECU (CONTINENTAL V56)

- Integration of the Stop and Start function with a (STTd) starter

1. Glossary

| Abbreviation | Definition |

| BSE | Coolant outlet housing |

| CMM | Engine management ECU |

| EOBD | European on-board diagnosis system |

| STTd | Stop and Start by starter motor function |

| VP | Passenger vehicle |

| VVT | Variable timing actuator |

2. EB2 FA engine introduction

The EB2 FA engine has been designed to meet the new EURO 6.2 emission control standard which comes into force from September 2017. (Official names "Euro 6.c and Euro 6.d TEMP").

These engines benefit from architecture and technology chosen with the aim of limiting fuel and carbon dioxide (CO2) consumption, while still delivering a superior performance.

The engine will be shared on the new platform, which is under development, that will arrive with a new B segment vehicle in 2019. The engine top required compacting due to the adaptation of the EB2 FA engine, EURO 6.2 emission control standard, into the engine environment of this new platform.

EB2 FA / d engine, EURO 6.2 emission control standard :

- Has been developed with the use of a standard B71 2010 synthetic oil with a 0W20 viscosity grade, reducing fuel consumption, protecting the emission control system and facilitating cold starting, especially at very low temperatures

- Remains compatible with the emission control synthetic oil, standard B71 2312 - 0W30

Modification of 25% of the EB2F engine parts, EURO 6.1 emission control standard, to achieve the EURO 6.2 emission control standard objectives and to reduce CO² emissions, but also for the installation on the new platform.

This engine also benefits :

- From a weight reduction of 1 kg

- From a reduction in consumption between 3.8 and 4.8%

- From an improvement in performance : The maximum torque changes from 116 to 118 Nm, and the maximum power changes from 59.2 to 61 kW

- From sharing 75% of the EB2 F engine parts, EURO 6.1 emission control standard, marketed since 2012

3. Major development of the EB2 FA engine

3.1. Objectives of the EURO 6.2 emission control standard

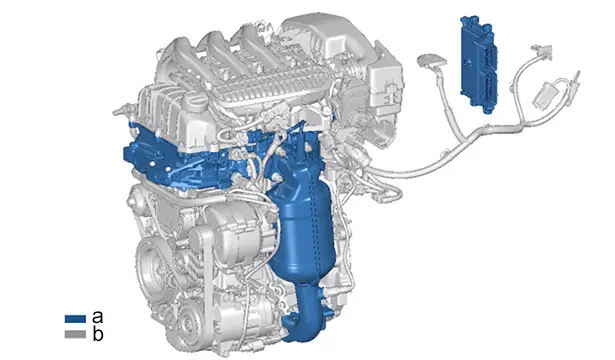

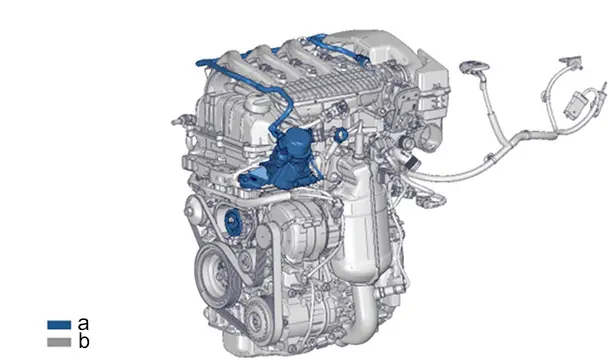

"a" : Parts specific to the EB2 FA engine compliant with the EURO 6.2 emission control standard.

"b" : Parts common to the EB2 F engine compliant with the EURO 6.1 emission control standard.

Modification :

- Of the geometry and heat treatment of the valves, exhaust valve and inlet valve seats, to take into account the increase of exhaust heat

- Of the cylinder head water jacket core in the valve seats area making it possible to limit the heat risk relating to the increase in exhaust temperature from 865°C for the EURO 5 emission control standard to 965°C for the EURO 6.2 emission control standard

- Of the cylinder head gasket that complies with the cooling circuit optimisation

Increase in the volume of the catalytic converter from 0.9 to 1.1 litres to ensure the processing of the increase in the gas flow from new regulatory cycles.

Improvement in the seal between the catalytic converter and the exhaust line.

Change to a proportional upstream oxygen sensor to achieve the "Catalytic converter European on-board diagnosis (EOBD) system" diagnostics in accordance with the stricter thresholds of the EURO 6.2 emission control standard.

New engine management ECU (CONTINENTAL) that complies with the EURO 6.2 emission control standard in fuel consumption and CO² emissions, by changes made to the technical specification.

Increase of the multi-core flash memory to 4 MB.

Silver 190-way connection.

Compatibility with proportional oxygen sensor.

3.2. Reduction in CO² emissions

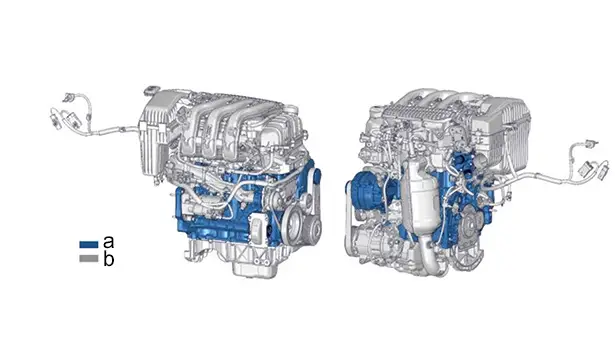

"a" : Parts specific to the EB2 FA engine compliant with the EURO 6.2 emission control standard.

"b" : Parts common to the EB2 F engine compliant with the EURO 6.1 emission control standard.

"a" : Parts specific to the EB2 FA engine compliant with the EURO 6.2 emission control standard.

"b" : Parts common to the EB2 F engine compliant with the EURO 6.1 emission control standard.

Modification of the cylinder block for fitting the cylinder liners from the EB2 engine turbocharger for improvement of mechanical losses relating to internal friction of the engine.

Modification :

- Of the exhaust and inlet camshafts by low friction treatment and of the modification of the valve lift, as well as a change of the exhaust and inlet sprocket. Modification also of the exhaust and inlet solenoid valves variable timing system (VVT), acting on the variable timing setting operating cycle

- Of the coolant outlet housing cover for integration of the thermostat electric control

- Of the pistons for hybrid liner compatibility, new scraper rings to improve the reciprocating gear friction pack

- Of the upper half-shells of the crankshaft 1 and 4 for improvement of crankshaft lubrication

Addition of piston head cooling jet.

Use of a new high-performance alternator a with built-in class 12 fan.

3.3. Installation on the new platform

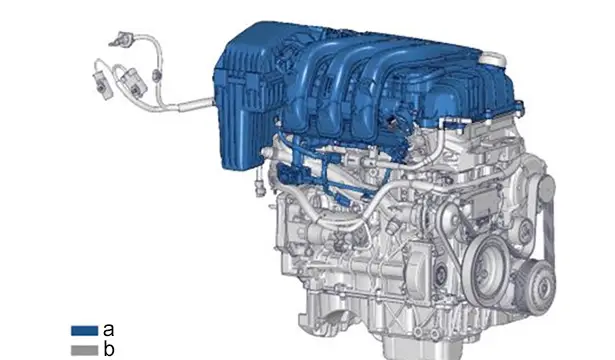

"a" : Parts specific to the EB2 FA engine compliant with the EURO 6.2 emission control standard.

"b" : Parts common to the EB2 F engine compliant with the EURO 6.1 emission control standard.

"a" : Parts specific to the EB2 FA engine compliant with the EURO 6.2 emission control standard.

"b" : Parts common to the EB2 F engine compliant with the EURO 6.1 emission control standard.

Strengthening and compacting of the fuel injection rail to improve fuel circuit performance against impact, and rotation at 180° of the fuel injectors, altering the direction of the electrical connectors towards the air inlet manifold interior.

Compacting of the air inlet manifold to allow for its installation under the bulkhead and scuttle.

Modification of the air filter assembly and its fixing for adaptation to the new under-bonnet location.

New engine harness.

Modification of the cylinder head cover oil separator by a reduction in volume (take-off of the crankcase fumes outlet dilution pipe), of the crankcase fumes dilution pipe and of the fuel vapour recovery pipe.

3.4. Improvement of engine functions and other modifications

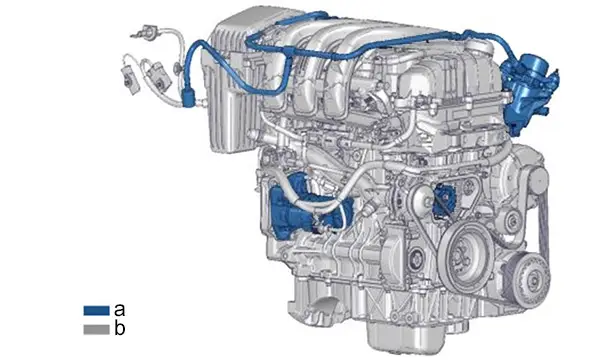

"a" : Parts specific to the EB2 FA engine compliant with the EURO 6.2 emission control standard.

"b" : Parts common to the EB2 F engine compliant with the EURO 6.1 emission control standard.

"a" : Parts specific to the EB2 FA engine compliant with the EURO 6.2 emission control standard.

"b" : Parts common to the EB2 F engine compliant with the EURO 6.1 emission control standard.

Starter with restart function to ensure the function Stop and Start and the fuel consumption reduction objectives.

Transition of the oil gauge to a metal core and new gauge colour : Light green.

New timing tensioner roller with a movement that is compatible with the new specification of the timing belt casing.

The vacuum generation will be set using an electric vacuum pump for "grand export" versions.

4. Identification of engines compliant with the Euro 6.2 emission control standard

Refer to the "Commercial launch of petrol engines that comply with the EURO 6.2 emission control standard" bulletin, available on the manufacturer’s aftersales documentation portal.

5. Technical data

| Engine | EB2 FAd | EB2 FA | EB2 FAM |

| Engine legislative type | HMM | HMR | HMJ |

| Commercial name | 1,2L VTi | 1,2L VTi | 1,2L VTi |

| Capacity (cc) | 1199 cc | 1199 cc | 1199 cc |

| Maximum power | 50 to 5750 rpm | 61 to 5750 rpm | 61 to 5750 rpm |

| Power | 68 HP | 82 HP | 82 HP |

| Maximum torque | 107 N.m at 2750 rpm | 118 N.m at 2750 rpm | 118 N.m at 2750 rpm |

| Bore x stroke (mm) | 75 mm x 90,5 mm | 75 mm x 90,5 mm | 75 mm x 90,5 mm |

| Compression ratio | 11 | 11 | 11 |

| Camshaft dephasers | Inlet and exhaust | Inlet and exhaust | Inlet and exhaust |

| injection | Indirect | Indirect | Indirect |

| Balance shafts | No | No | No |

| Transmission | EURO 6.2 (EURO 6.c) | EURO 6.2 (EURO 6.c) | EURO 6.1 (EURO 6.b) |

6. Engine maintenance

CAUTION : During servicing operations, check the engine coolant level and top it up, if necessary.

The maintenance conditions are described in the servicing schedule taken from the manufacturer’s Aftersales documentation portal and given to the customer on handover.

The information relating to the maintenance conditions is available on the manufacturer’s Aftersales documentation portal :

- Enter the vehicle’s VIN

- Documentation

- Technical documentation

- Maintenance - Service schedules

6.1. Maintenance programme:

To benefit from the full servicing schedule and the latest updates : Consult the servicing schedule on the manufacturer’s aftersales documentation portal ; Using the VIN.

| Systematic operations | |

| Europe : In normal conditions of use | 25 000 km or 1 year |

| Europe : In arduous conditions of use | 15 000 km or 1 year |

| Outside Europe : With dispensation | 15 000 km or 1 year |

| Outside Europe | 10 000 km or 1 year |

6.2. Timing belt

| Timing belt | Timing kit | |

| Europe : In normal conditions of use | 100 000 km or 6 year | 200 000 km or 12 year |

| Europe : In arduous conditions of use | 105 000 km or 6 year | 210 000 km or 12 year |

| Outside Europe : With dispensation | 105 000 km or 6 year | 210 000 km or 12 year |

| Outside Europe | 100 000 km or 6 year | 210 000 km or 12 year |

6.3. Configuration of the servicing schedule

On the diagnostic tool, the "Maintenance" menu permits access :

- To the servicing operations

- To the maintenance operations

- To the 12 V battery state of charge measuring operation

- The frequency of the servicing depends on the countries and the conditions of use. Refer to the organisation bulletin which covers this subject

6.4. Engine oil

CAUTION : Only engine oils which comply with the PSA PEUGEOT CITROËN standards are authorised.

CAUTION : Only the following oil is permitted for the EB2 FA engine compliant with the Euro 6.2 emission control standard.

| Type of oil permitted | Specifications of the standard |

| 0W20 | B71 2010 |

| 0W30 | B71 2312 |

In order to benefit from the latest updates : Refer to the "Recommended consumables: engine oils" method on the manufacturer’s aftersales documentation portal

.

.

6.5. Engine oil capacity

| Engine | Type of draining | Maximum oil volume |

| EB2 FAEB2 FAdEB2 FAM | With replacement of the filter cartridge | 3,25 litres |

| Without replacement of the filter cartridge | 3 litres | |

| EB2 FAEB2 FAdEB2 FAM | ConsumableVolume between minimum and maximum | 1 litre |

In order to benefit from the latest updates ; Refer to the method : Checking and adjusting values

: EB engine type

: EB engine type

.

.

7. Aftersales documentation

The aftersales documentation can be found on the manufacturer’s aftersales documentation portal ; Using the VIN :

- The aftersales technical documentation comprises

- The principles of operation that explain all the functions of the engine

- The diagnostic aids

- The tables of fault codes

- The replacement parts catalogue

- The repair and maintenance procedures

- The relevant repair time schedules

- The documentation for specific tools

8. Repair

Refer to the repair procedures.

8.1. 12 V battery disconnection - reconnection operations

CAUTION : For vehicles fitted with the Stop and Start function, use genuine batteries to protect their service life.

Refer to the method : Operations to be performed prior to a disconnection and following a reconnection of the battery

.

.

8.2. Mechanical repair

Refer to the repair procedures : Removing - refitting : Mechanical components: .

9. Special tools

The EB2FA engine that complies with the EURO 6.2 emission control standard requires special tools developed for the EB2 F engine, EURO 6.1 emission control standard.

No special tools.

10. Warranty

No special feature for this engine.

11. Recall campaigns

No special feature for this engine.

12. Reporting of information

Refer to the document "Organisation bulletin: feedback to customers" for the vehicle.

Manufacturer’s Aftersales documentation portal : "DOCUMENTATION" tab ↦Vehicle / General ↦Repair procedures ↦Data - Identifications.

13. Technical assistance

The "Dealer Issue Detection Assistance" (DID-A) is used to contact technical assistance.

Observe the DID standards (Manufacturer’s Aftersales documentation portal : "Incidents-Assistance" tab ↦DID practical information ↦DID standards) :

- Relevance standard

- Quality standard

N.B. : Refer to the organisation bulletin which covers this subject.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image