Peugeot 308: Organisation bulletin : Modification of the servicing interval for EB engines and of the preventative systematic check of the timing belt

1. Introduction

The purpose of this bulletin is to inform authorized repairers (RA) of the modification :

- Of the servicing schedule for the naturally aspirated EB engines and turbocharged EB engines

- Of the implementation of the systematic check of the turbocharged engines’ timing belt

It thus recalls the need to comply with the basic rules for using fuels and additives, and engine oils. The engines must be drained with engine oil that complies with PSA standards and the recommended servicing schedule must be strictly observed.

In the event of damage or engine failure, the repairer who carried out maintenance on the vehicle may be held liable. Each authorised repairer (RA) must use oil that meets PSA Group standards. The authorised repairer must show the grades of oil used and the PSA Group standard on customer invoices.

If a non-compliant oil is used, the PSA Group can refuse to accept any responsibility for an engine incident.

2. Context

The EB engine family with 3 cylinders has been designed to also meet the cost reduction (downsizing) requirements of the PSA Group.

As such, the engine has a reduced volume of oil compared to competitors and a timing belt casing with an oil-bathed belt to minimise these operating noises.

The durability of the timing belt is intrinsically linked :

- To compliance with the servicing schedule frequency,

- To the strict use of consumables and parts recommended by the manufacturer

N.B. : During a change, the engine oil quantity is 3,25 litres for the naturally aspirated engine and 3,5 litres for the turbocharged engine.

Certain country and/or special use circumstances may cause premature breakdown of the timing belt; as a result, to protect its customers, the PSA Group has decided to :

- Decrease the service interval from 25 000 km or 1 year to 20 000 km or 1 year for all European countries

- Add a systematic preventive checking operation to the timing belt servicing schedule for the turbocharged engine

- To modify the timing belt replacement frequency (Refer to section 5)

3. Modification of the service interval

The oil-bathed timing belt for the EB2 engines is located directly in the engine, passing through the cylinder block and cylinder head.

The oil-bathed timing belt is subject to internal mechanical operating variations such as oil temperature and oil quality.

During operation, the oil in an engine is diluted.. This phenomenon, which is normal to a point, charges the oil with fuel and has an aggressive effect on the timing belt when :

- The oil used is not that recommended in the manufacturer’s specifications. It must comply with the B71xxxx specifications and standard, grade, manufacturer or brand. This information is available in the bulletin "Recommended consumables: Engine oil" updated annually on the manufacturer’s after-sales documentation portal. This bulletin lists the PSA Group approved lubricant products by engine type and by country (climate zones).(*)

- The service interval is not complied with. In addition to the systematic operations required for the engine and vehicle to maintain performance and meet pollution standards, oil renewal ensures optimum engine operation. An engine oil comprises elements with a limited lifespan and limited conditions of use. To ensure calcium, magnesium, phosphorus and zinc levels and prevent oil degradation, these elements are dispersant additives, friction modifiers, anti-corrosives, antioxidants and detergents. If these elements are missing or degraded, this will make chemical attacks on the timing belt more likely, leading to premature breakdown and engine malfunction which may cause engine failure

- The use of additives in oil or fuel directly affects the composition of the oil; any addition can destroy its balance and lead to degradation of both the oil and the engine. For a marketing area, or to respond to a malfunction symptom associated with fault codes to clean the engine : Only the additives recommended by the PSA Group are authorised (UNIK and UNIK+) and are used in preventive or curative maintenance according to specific criteria identified

- The oil level in the engine is not complied with. The EBengine, with one of the smallest oil volumes in its class, has a defined operating mode with a range between the minimum and maximum levels. Oil consumption is normal in the operating cycle of an engine, but the oil level must remain within the defined range to optimise engine performance (**). An oil level below the minimum will lead to degradation of the timing belt and affect engine performance which can result in failures due to ageing of the oil. Components are present on the EB engines and allow monitoring of this oil level : A manual oil gauge is present on all engine versions and can be associated with an oil level sensor that returns the information to the instrument panel each time a driving cycle is started

N.B. : (*)After entering the VIN for the relevant vehicle into the manufacturer’s aftersales documentation portal, this bulletin can be accessed in several ways.

I.e. :

- Via the following path : vehicles ↦General ↦Repair procedures ↦Select the bulletin: " Recommended consumables : Engine oils" Under the section : Data - identification

- By entering the part number "E4AB010AP0" in the search field of the manufacturer’s aftersales documentation portal

N.B. : (**)Oil must be topped up between each service interval. Oil can be topped up by the customer and the network. The network should recommend this practice to its customer when returning the vehicle after servicing or on purchase.

To preserve the engine oil characteristics, the service interval for naturally aspirated EB2 and turbocharged EB2 engines, still in production, has changed to 20 000 km (12 500 miles) or 1 year in normal use.

This application is effective on all vehicles produced since October 2019 and is valid for all European countries.

Arduous use remains at 15 000 km (10 000 miles) or 1 year.

For countries outside Europe, the service interval remains at 10 000 km (6 000 miles) or 1 year.

From 1 November 2021, the servicing schedules for countries outside Europe applied in Israel and in Turkey are changing to preserve the timing belt : Normal use remains at 15 000 km (10 000 miles) or 1 year and arduous use at 10 000 km (6 000 miles) or 1 year has been added.

Thus, in summary.

| Engine version | Normal usage(Europe) | Severe usage(Europe) | World(Outside Europe) |

| Naturally aspirated EB2 engine | 20 000 km (12 500 miles) or 1 year | 15 000 km (10 000 miles) or 1 year | 10 000 km (6 000 miles) or 1 year |

| Turbocharged EB2 engine | 20 000 km (12 500 miles) or 1 year | 15 000 km (10 000 miles) or 1 year | 10 000 km (6 000 miles) or 1 year |

N.B. : The values in miles are not strictly derived from the conversion of kilometres but are those included in the vehicle maintenance display ECU.

N.B. : No retroactive application for vehicles produced before October 2019.

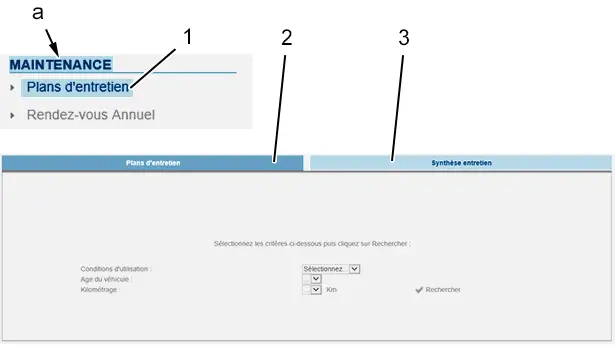

(1)"servicing schedules” menu.

(2)Service schedules.

(3)Servicing summary.

"a""maintenance" section.

CAUTION : Only information from the manufacturer’s aftersales documentation portal and strictly related to the chassis number of the customer’s vehicle is valid.

After entering the VIN for the relevant vehicle into the manufacturer’s aftersales documentation portal.

Check the servicing schedule and interval to be applied to the vehicle in the manufacturer’s aftersales documentation portal.

Via the following path : "maintenance" menu(In "a") ↦ Service schedules(1) ↦ Tab : Service schedules(2) / Servicing summary(3) (Enter the vehicle information).

N.B. : The servicing schedule and summary show the precise service intervals (mileage and year) required, and in particular the quality and quantity of engine oil to be replaced in order to comply with the manufacturer’s recommendations.

4. Systematic check of the timing belt of the turbocharged EB engine

4.1. Introduction

As explained earlier, fuel and oil affect the timing belt properties. The turbocharged engine is more affected by these variations in fuel and oil quality due to its level of performance.

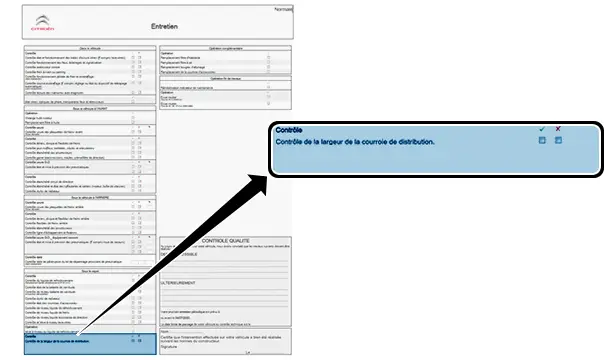

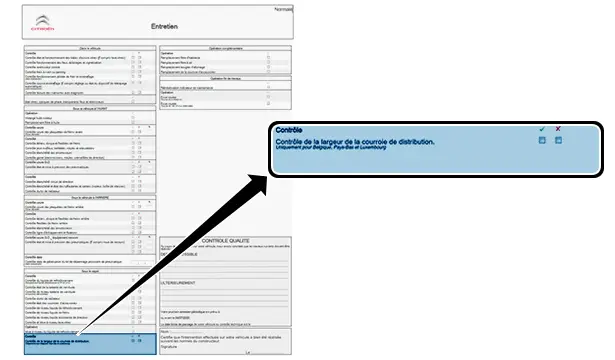

This may result in the intrinsic qualities of the timing belt being changed. The variations in the width of the timing belt can be controlled using a specific tool developed for this purpose.

N.B. : This check is included in the list of routine "Maintenance" operations to be carried out during vehicle servicing and is included in the service time package 1.

4.2. Turbocharged EB engine

CAUTION : To avoid the risk of engine fault or failure, this preventive checking operation is performed at every service interval when the turbocharged EB engines are drained.

4.3. Naturally aspirated EB engine

The refining of fuels distributed by certain oil producers in Benelux and Finland has been identified as a factor contributing to the premature breakdown of the timing belt.

This control solution based on the timing belt width is also applied to naturally aspirated EB engines for Belgium, the Netherlands, Luxembourg and Finland,.

4.4. Check of the timing belt width

The procedure for checking the timing belt width is described in the method available in manufacturer’s aftersales documentation portal (Refer to procedure B1ED013XP0).

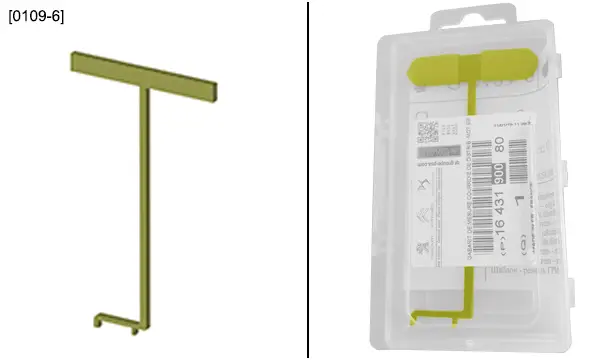

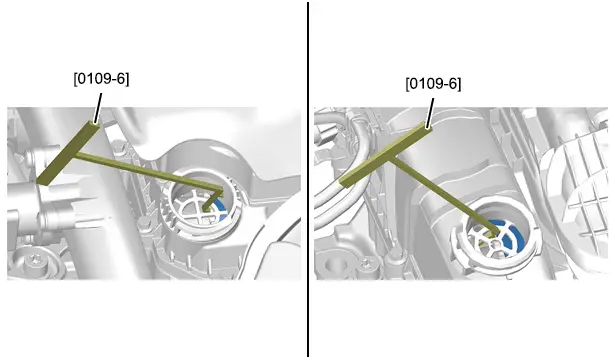

A specific tool has been developed for this purpose :.

Timing belt width checking jig/ Storage box: [0109-6] (Part number: 16 431 900 80).

N.B. : The check can be carried out without disassembling any engine part other than the engine oil filler cap and entails no risk to the timing belt.

During the check, the tool [0109-6] is introduced through the oil filler neck, and the conformity criterion for the timing belt can be interpreted immediately (OK - NOK).

CAUTION : The only criterion which authorises the replacement of the timing belt before the normal belt servicing interval is the width check that is carried out at each service to detect inflated belts (evidence of chemical attack).

N.B. : If the result of the timing belt width check conforms to the specifications, the presence of some fibres located on the side of the timing belt will certainly not cause a failure. This does not authorise the replacement of the timing belt.

N.B. : If the result of the timing belt width check is NOK : Proceed as per Technical Service Bulletin (TSB) B1FW013CQ0.

CAUTION : The checking template must be kept in its rigid storage box to maintain its accuracy.

5. Modification to the timing belt replacement frequency

To maintain optimum engine performance and to supplement preventive EB engine maintenance and control measures, the timing belt replacement frequency has been increased.

From 04/04/2017

| Replacement | Normal usage(Europe) | Severe usage(Europe) | World(Outside Europe) |

| Timing belt | 100 000 km (62 500 miles) or 6 years | 105 000 km (70 000 miles) or 6 years | 100 000 km (60 000 miles) or 6 years |

| Timing kit | 200 000 km (125 000 miles) or 12 years | 210 000 km (140 000 miles) or 12 years | 200 000 km (120 000 miles) or 12 years |

From 23/12/2020

| Replacement | Normal usage(Europe) | Severe usage(Europe) | World(Outside Europe) |

| Timing belt | 100 000 km (62 500 miles) or 6 years | 90 000 km (60 000 miles) or 6 years | 90 000 km (54 000 miles) or 6 years |

| Timing kit | 200 000 km (125 000 miles) or 12 years | 180 000 km (120 000 miles) or 12 years | 180 000 km (108 000 miles) or 12 years |

N.B. : The values in miles are not strictly derived from the conversion of kilometres but are those included in the vehicle maintenance display ECU.

When replacing the timing belt, either to comply with the recommendations of the vehicle servicing schedule or following the timing belt width check, the replacement should be carried out retroactively.

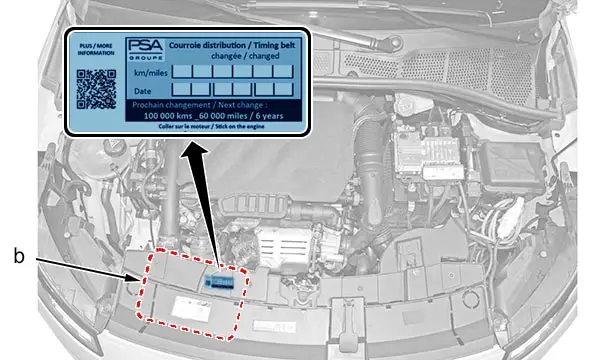

This replacement recommendation will be specified by 2 adhesive change labels showing the mileage and date of the replacement operation.

These labels also remind the customer and the network of the recommended replacement date. A QR code, universally accessible, is shown on the adhesive change labels and recalls the recommendations and usage guidelines for the vehicle.

These change labels can be found in the packaging of the original replacement timing belt as well as in the timing kits for the EB engines.

N.B. : These change labels must be used when replacing the timing belt, demonstrating the use of a genuine part and specifying when the next replacement is due.

A label specially for the engine compartment must be affixed, if possible, in alignment with the timing belt (In the area "b").

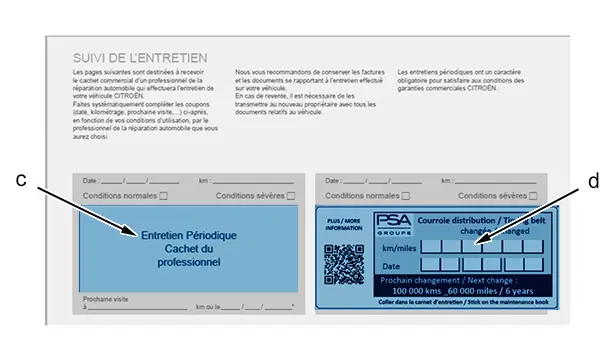

A second label specially for the service log must be affixed to the "MAINTENANCE FOLLOW-UP" page alongside the official dealership stamp.

Fill in the headers in 2 locations :

- Add the dealership stamp(In "c")

- Affix the appropriate completed label(In "d")

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image