Peugeot 308: Organisation bulletin : Procedure for returning the traction battery (PHEV)

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : Only those personnel that have received training specific to electric vehicles are qualified to operate on the vehicle(observe the regulations in force in the respective country).

ESSENTIAL : Only the garages ("e-Expert Center" and "e-Repair Center") qualified to work on the traction battery components are authorised to remove a damaged traction battery.

ESSENTIAL : Switch the vehicle’s power off

.

.

N.B. : This organisation bulletin is applicable for countries of the European Union, Norway, Switzerland, the United Kingdom and Iceland. For other countries, contact the subsidiary or importer of the country of sale.

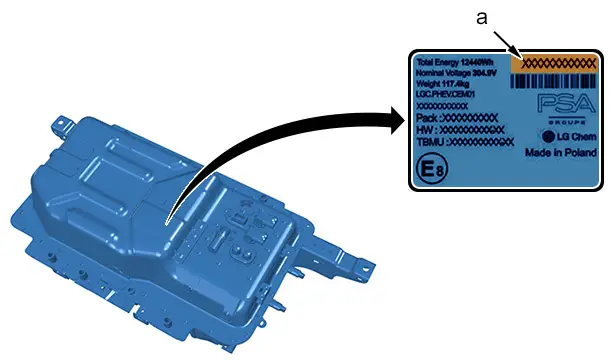

1. Identification of the "Li-Ion" traction battery

PHEV DRIVE TRAIN

(1) Traction battery (Supplier : LG Chem ).

"a" Identification of the "Li-Ion" traction battery (Battery Identification Number : BIN).

PHEV DRIVE TRAIN

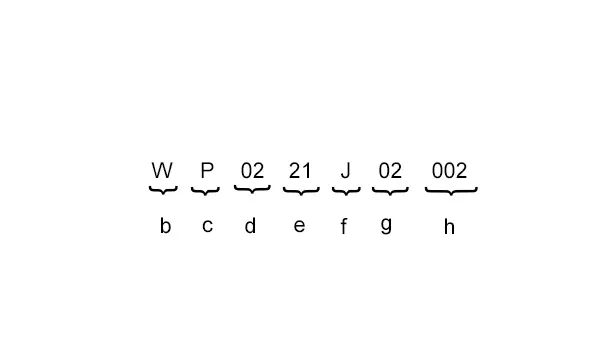

| Identification | Description | - | Value |

| "b" | Pack V2 | - | W |

| "c" | Production site | Korea | K |

| Poland | P | ||

| "d" | Production line | CWA 2 | 02 |

| "e" | Year of production | - | 18 - 99 |

| "f" | Production month | - | A - L |

| "g" | Production day | - | 01 - 31 |

| "h" | Pack number | - | 001 - 999 |

2. Qualification of the status of a traction battery (LI-ION)

Categorise the status of the safe or unsafe traction battery according to the criteria defined in sections 2.1 and 2.2.

Circle the status that best describes the status of the vehicle’s traction battery and at a later stage attach it in the folder of the part to be transported.

2.1. Safe traction battery

A safe traction battery can be categorised in 3 ways :

- "in working order"

- "not operational"

- "faulty"

A traction battery is considered to be in "working order" if it fulfils all of the following conditions :

- No fault visible from the outside

- Traction battery diagnostics possible

- Normal operating characteristics (uniform and performance as expected)

A traction battery is considered "not operational" if it fulfils all of the following conditions :

- No fault visible from the outside

- Traction battery diagnostics possible

- Uniform characteristics but insufficient to operate and must be declared not operational

A traction battery is considered "faulty" if it fulfils all of the following conditions :

- No fault visible from the outside

- Traction battery diagnostics possible

- Differing and abnormal characteristics preventing its operation

2.2. Unsafe traction battery

An unsafe traction battery has one or more of the following irreversible defects :

- Distortion following an impact

- Suspect odours

- Discharge of fluid

- Appearance of smoke or flames

- Insulation fault

- Diagnostics cannot be carried out using the diagnostic tool

3. Situations to be dealt with

Before removing the traction battery from the vehicle, within and outside the traction battery warranty period :

- Accurately identify the serial number of the traction battery (BIN) as well as the vehicle’s VIN

- Obtain approval from technical assistance to remove the used traction battery for the VIN and the BIN concerned (Technical assistance validates the safe/unsafe status of the traction battery)

The different situations to be dealt with are :

- Used safe traction battery to be sent to the replacements parts distributor

(Refer to section 3.1)

(Refer to section 3.1) - Used unsafe traction battery to be sent to the replacement parts distributor

(Refer to section 3.2)

(Refer to section 3.2) - Used unsafe traction battery to be sent for recycling

(Refer to section 3.3)

(Refer to section 3.3) - Used safe traction battery to be sent for recycling

(Refer to section 3.4)

(Refer to section 3.4)

3.1. Used safe traction battery to be sent to the replacements parts distributor

3.1.1.Introduction.

This chapter only applies :.

If the traction battery is the subject of a request to return parts to the replacement parts distributor (Information available in SAGAI).

N.B. : In accordance with the procedure described in the manufacturer’s aftersales documentation portal : Warranty contract ↦Practical warranty information ↦How is the return of replaced parts to the brand processed? ↦Processing the return of parts to the Warranty Parts Centre (WPC).

3.1.2.Replacement traction battery ordering procedure (If necessary) :

- Contact technical assistance to obtain the "replacement parts" number of the replacement traction battery

- If the incident occurs during the traction battery warranty period, contact the warranty platform to obtain the expenditure approval

- Order the replacement traction battery

- Contact the "replacement parts" distribution hub or the importer and agree on a date for the replacement traction battery to be delivered

- Check whether there is a forklift truck with a capacity suitable for unloading operations . If there is no forklift available at the Authorised Repairer’s premises, the replacement parts distributor must provide the vehicle or handling device suitable for offloading and loading the traction battery and/or its packaging

N.B. : The packaging of the new traction battery is used for returning the used safe traction battery, which is returned on the day of the delivery by the same courier.

3.1.3.Operations to be carried out before the standard container arrives and the traction battery is returned.

Remove the traction battery .

Remove the traction battery from the lifting table (Refer to the method : Packing traction batteries).

Store the traction battery in the designated exclusion area inside the building.

Print out and fill in the returned traction battery status classification document

.

.

Scan the traction battery status classification document and attach it to the Dealer Issue Detection (DID) via the application.

Gather together the documents (traction battery status classification document) in order to attach them to the packaged traction battery.

3.1.5.Procedure to be carried out when the courier arrives and the container is received.

CAUTION : After receiving the container, the time taken to prepare and load into the courier’s vehicle must not exceed one hour.

Package the used traction battery into the standard container

.

.

Place the traction battery status classification document inside the secure container.

N.B. : The traction battery identification number (BIN) must be clearly marked on the outside of the standard container.

Put the traction battery identification number (BIN) on the outside of the standard container.

Load the packaged traction battery into the courier’s vehicle.

Give the courier the documents relating to the transport of hazardous material in compliance with the legislation in force in the country (Example : For Europe, there are the ADR regulations ).

- Documents to be presented by the courier :

- Driver’s training certificate

- Identification document with photo for each member of the team

- Written instructions

- Document to be provided by the sender :

- The transport document (ADR declaration)

- The document format is free : See example at the end of the document

- This document must be completed in the official language of the country of dispatch, but also in French or English if this is not the case

3.2. Used unsafe traction battery to be sent to the replacement parts distributor

3.2.1.Introduction.

This chapter only applies :.

If the traction battery is the subject of a request to return parts to the replacement parts distributor (Information available in SAGAI).

N.B. : In accordance with the procedure described in the manufacturer’s aftersales documentation portal : Warranty contract ↦Practical warranty information ↦How is the return of replaced parts to the brand processed? ↦Processing the return of parts to the Warranty Parts Centre (WPC).

ESSENTIAL : Any personnel working on a vehicle with an unsafe traction battery must have received electric vehicle-specific training and be authorised to work on such vehicles (observe the regulations in force in the respective country).

The authorised repairer permitted to deal with an unsafe traction battery must :

- Have received special training

- Have an exclusion area in which to store the vehicle and the traction battery (risk of leaks, fire etc.)

CAUTION : Store the vehicle with a suspected unsafe traction battery in the exclusion area outside the building and carry out the operations for removing the used traction battery within a short period of time..

N.B. : Store the used unsafe traction battery in the weather-protected exclusion area outside the building while waiting for the secure container to be delivered.

3.2.2.Replacement traction battery ordering procedure (If necessary) :

- Contact technical assistance to obtain the "replacement parts" number of the replacement traction battery

- If the incident occurs during the traction battery warranty period, contact the warranty platform to obtain the expenditure approval

- Order the replacement traction battery

- Contact the "replacement parts" distribution hub or the importer and agree on a date for the replacement traction battery to be delivered

- Check whether there is a forklift truck with a capacity suitable for unloading operations . If there is no forklift available at the Authorised Repairer’s premises, the replacement parts distributor must provide the vehicle or handling device suitable for offloading and loading the traction battery and/or its packaging

3.2.3.Procedure for procuring the secure container.

Procuring the secure container :

- Order a secure container through the replacement parts network

- Contact the "replacement parts" distribution hub or the importer and agree on a date for the secure container to be delivered and for the used unsafe traction battery to be returned to the reconditioning centre

- Check whether there is a forklift truck with a capacity suitable for unloading operations

3.2.4.Operations to be carried out before the secure container arrives and the unsafe traction battery is returned.

Remove the traction battery .

Remove the traction battery from the lifting table (Refer to the method : Packing traction batteries).

Store the traction battery in the weather-protected exclusion area outside the building.

N.B. : Protect the unsafe traction battery if the exclusion area outside the building is not weather-protected.

Print out and fill in the traction battery status classification document

.

.

Scan the traction battery status classification document and attach it to the Dealer Issue Detection (DID) via the application.

Gather together the documents (traction battery status classification document) in order to attach them to the packaged traction battery.

3.2.5.Procedure to be carried out when the courier arrives and the container is received.

CAUTION : After receiving the container, the time taken to prepare and load into the courier’s vehicle must not exceed 1 hour.

CAUTION : The courier delivering the secure container only leaves with the packaged used unsafe traction battery and no other goods.

Package the used traction battery in the secure container

.

.

Place the traction battery status classification document inside the secure container.

N.B. : The traction battery identification number (BIN) must be clearly marked on the outside of the secure container.

Put the traction battery identification number (BIN) on the outside of the secure container.

Load the packaged traction battery into the courier’s vehicle.

Give the courier the documents relating to the transport of hazardous material in compliance with the legislation in force in the country (Example : For Europe, there are the ADR regulations ).

- Documents to be presented by the courier :

- Driver’s training certificate

- Identification document with photo for each member of the team

- Written instructions

- Document to be provided by the sender :

- The transport document (ADR declaration)

- The document format is free : See example at the end of the document

- This document must be completed in the official language of the country of dispatch, but also in French or English if this is not the case

3.3. Used unsafe traction battery to be sent for recycling

3.3.1.Introduction.

This chapter only applies in the case of an unsafe traction battery, including :

- A non-repairable vehicle that has been involved in an accident

- A vehicle at the end of its service life

ESSENTIAL : Any personnel working on a vehicle with an unsafe traction battery must have received electric vehicle-specific training and be authorised to work on such vehicles (observe the regulations in force in the respective country).

The authorised repairer permitted to deal with an unsafe traction battery must :

- Have received special training

- Have an exclusion area in which to store the vehicle and the traction battery (risk of leaks, fire etc.)

CAUTION : Store the vehicle with a suspected unsafe traction battery in the exclusion area outside the building and carry out the operations for removing the used traction battery within a short period of time..

N.B. : Store the used unsafe traction battery in the weather-protected exclusion area outside the building while waiting for the secure container to be delivered.

3.3.2.Replacement traction battery ordering procedure (If necessary) :

- Contact technical assistance to obtain the "replacement parts" number of the replacement traction battery

- If the incident occurs during the traction battery warranty period, contact the warranty platform to obtain the expenditure approval

- Order the replacement traction battery

- Contact the "replacement parts" distribution hub or the importer and agree on a date for the replacement traction battery to be delivered

- Check whether there is a forklift truck with a capacity suitable for unloading operations . If there is no forklift available at the Authorised Repairer’s premises, the replacement parts distributor must provide the vehicle or handling device suitable for offloading and loading the traction battery and/or its packaging

3.3.3.Procedure for procuring the secure container.

CAUTION : The courier delivering the secure container then leaves with nothing.

Procedure for procuring the secure container :

- Order a secure container through the replacement parts network

- Contact the "replacement parts" distribution hub or the importer and agree on a date for the secure container to be delivered

- Check whether there is a forklift truck with a capacity suitable for unloading operations

3.3.4.Operations to be carried out after the secure container has arrived and before the traction battery is returned.

Record the traction battery state of health (SOH) and state of charge (SOC) on the instrument panel (If technically feasible).

Remove the traction battery .

Remove the traction battery from the lifting table (Refer to the method : Packing traction batteries).

Store the traction battery in the weather-protected exclusion area outside the building.

N.B. : Protect the unsafe traction battery if the exclusion area outside the building is not weather-protected.

Print out and fill in the traction battery status classification document

.

.

Scan the traction battery status classification document and attach it to the Dealer Issue Detection (DID) via the application.

If no new battery is to be ordered:Enter a credit claim in "SAGAI" for the removal labour to be reimbursed (Use the allocation code "BAT" ).

Complete the "Collection and recycling request" form

.

.

Send the completed form to the address of the country’s contact

.

.

Package the used traction battery in the secure container

.

.

Gather together the documents (traction battery status classification document) in order to attach them to the packaged traction battery.

Place the packed traction battery in the collection area.

Wait to be contacted by the local representative of the "PSA Groupe" company to arrange a date for the used traction battery to be collected.

3.3.5.Procedure to be carried out when the courier arrives.

CAUTION : After receiving the container, the time taken to prepare and load into the courier’s vehicle must not exceed 30 minutes.

Load the packaged traction battery into the courier’s vehicle.

Give the courier the documents relating to the transport of hazardous material in compliance with the legislation in force in the country (Example : For Europe, there are the ADR regulations).

- Documents to be presented by the courier :

- Driver’s training certificate

- Identification document with photo for each member of the team

- Written instructions

- Document to be provided by the sender :

- The transport document (ADR declaration)

- The document format is free : See example at the end of the document

- This document must be completed in the official language of the country of dispatch, but also in French or English if this is not the case

N.B. : When the courier arrives to collect the packaged traction battery, the conditions below will result in a penalty to be paid by the dealership.

Conditions resulting in penalties to be paid by the dealership :

- Absence of the person responsible for providing the packed traction battery for recycling

- Packaged traction battery unavailable

- Packaged traction battery inaccessible

- Traction battery not packed

- Delay of more than 30 minutes awaiting availability

N.B. : For any specific packaging containing waste other than the traction batteries, a surcharge bill will be sent directly to the dealership with no possibility of reimbursement by the PSA Groupe (Refer to the prices listed in the "Collection and recycling request" form).

3.4. Used safe traction battery to be sent for recycling

3.4.1.Introduction.

This section mainly applies in one of the following instances :

- Traction battery at the end of its service life

- Traction battery non-repairable

- The return of the traction battery is not requested in accordance with a quality requirement or a campaign

3.4.2.Replacement traction battery ordering procedure (If necessary) :

- Contact technical assistance to obtain the "replacement parts" number of the replacement traction battery

- If the incident occurs during the traction battery warranty period, contact the warranty platform to obtain the expenditure approval

- Order the replacement traction battery

- Contact the "replacement parts" distribution hub or the importer and agree on a date for the replacement traction battery to be delivered

- Check whether there is a forklift truck with a capacity suitable for unloading operations . If there is no forklift available at the Authorised Repairer’s premises, the replacement parts distributor must provide the vehicle or handling device suitable for offloading and loading the traction battery and/or its packaging

N.B. : The packaging of the new traction battery is used for returning the used traction battery.

3.4.3.If ordering a replacement traction battery is not necessary :

- Order standard packaging for packing the safe traction battery through the usual replacement parts channels

- Check whether there is a forklift truck with a capacity suitable for unloading operations

- Enter a credit claim in "SAGAI" for the removal labour and specific packaging to be reimbursed (Use the allocation code "BAT" )

3.4.4.Operations to be carried out before the standard container arrives and the traction battery is returned.

Record the traction battery state of health (SOH) and state of charge (SOC) on the instrument panel (If technically feasible).

Remove the traction battery .

Remove the traction battery from the lifting table (Refer to the method : Packing traction batteries).

Store the traction battery in the designated exclusion area inside the building.

Print out and fill in the traction battery status classification document

.

.

Scan the returned part status classification document and attach it to the Dealer Issue Detection (DID) via the application.

Complete the "Collection and recycling request" form

.

.

Send the completed form to the address of the country’s contact

.

.

Put the used traction battery in the standard packaging that was either ordered or provided with the replacement part.

Gather together the documents (traction battery status classification document) in order to attach them to the packaged traction battery.

Wait to be contacted by the local representative of the "PSA Groupe" company to arrange a date for the used traction battery to be collected.

3.4.5.Procedure to be carried out when the courier arrives.

CAUTION : After receiving the container, the time taken to prepare and load into the courier’s vehicle must not exceed 30 minutes.

N.B. : The container of the new traction battery is used for returning the used traction battery, which is returned on the day of the delivery by the same courier.

Load the packaged traction battery into the courier’s vehicle.

Give the courier the documents relating to the transport of hazardous material in compliance with the legislation in force in the country (Example : For Europe, there are the ADR regulations).

The following documents must be aboard the transport unit in compliance with ADR regulations.

- Documents to be presented by the courier :

- Driver’s training certificate

- Identification document with photo for each member of the team

- Written instructions

- Document to be provided by the sender :

- The transport document (ADR declaration)

- The document format is free : See example at the end of the document

- This document must be completed in the official language of the country of dispatch, but also in French or English if this is not the case

N.B. : When the courier arrives to collect the packaged traction battery, the conditions below will result in a penalty to be paid by the dealership.

Conditions resulting in penalties to be paid by the dealership :

- Absence of the person responsible for providing the packed traction battery for recycling

- Packaged traction battery unavailable

- Packaged traction battery inaccessible

- Traction battery not packed

- Delay of more than 30 minutes awaiting availability

N.B. : For any specific packaging containing waste other than the traction battery, a surcharge bill will be sent directly to the dealership with no possibility of reimbursement by the PSA Groupe (Refer to the tariff on the "Collection and recycling request" form).

4. Obtaining the "Collection and recycling request" form (Traction battery)

N.B. : The "Collection and recycling request" form is available on the manufacturer’s Aftersales documentation portal.

| Type of access | Address |

| Internet | https://public.servicebox-parts.com/dtt/AP/Diag_AP/AP/donnees/DOC/Unique_battery_recycling_form_V1.xlsx |

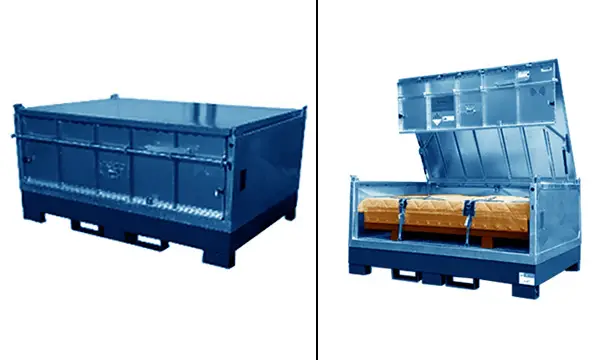

5. List of packaging

5.1. Safe traction battery packaging

Standard packaging (PHEV).

| Description | Reference | DimensionsL x l x H | Weight when empty | Total mass (Packaged traction battery ) |

| Standard packaging | XXXXXXXX | 1600 x 720 x 550 | 55 kg | Between XXX and XXX kg |

5.2. Unsafe traction battery packaging

Secure packaging (PHEV).

| Description | Reference | DimensionsL x l x H | Weight when empty | Total mass (Packaged traction battery ) |

| Secure packaging | 1677069980 | 2000 x 1400 x 990 | 625 kg | Between XXX and XXX kg |

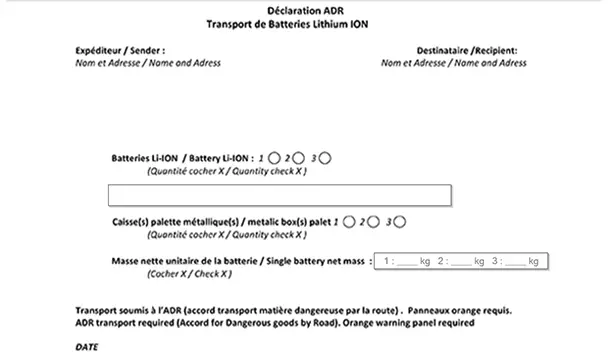

6. Transport document (ADR declaration)

6.1. Presentation

The ADR declaration must include the following particulars :

- The UN number : (UN 3480) (*)

- The name or description of the shipment : Lithium ion batteries(*)

- The label model number : 9 (*)

- The packing group: GE II (*)

- The number and description of the packages (X box(s) in …) (*)

- The name and address of the consignor

- The name and the address of the consignee(*) (**)

- The tunnel restriction code : (E) (Passage forbidden through tunnels of category E)

N.B. : (*) : Items to be filled in or checked.

N.B. : (**) : If sending for recycling, the name and address of the recipient should be provided by the recycling company carrying out the operation.

N.B. : (**) : If returning to a replacement parts distributor, the name and address of the distribution hub or importer.

6.2. ADR declaration example:

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image