Peugeot 308: New vehicle preparation : Dealing with faults after exterior preparation of the vehicle

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

1. Subject and field of application

List of the different faults that may be found following exterior deprotection of the vehicle.

Presentation of the corrective measures to be applied during new vehicle preparation to return the vehicle to conformity.

After dealing with the faults, resume the new vehicle preparation procedure at section : "Exterior preparation of the vehicle".

2. Processing faults

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

CAUTION : Ideally use the products recommended by the manufacturer

.

.

Types of faults found :

- Deposits of adhesive from the cover or from the adhesive film on the bodywork or glass

- Difference in shade on a partially protected component

- Stains in the paint

- Marks on the paint

- Micro-scratches

- Deposits coming from the brake linings of the transport trucks

- Deposits of burnt particles from overhead railway electric cables

- Deposits of paint particles

- Traces left by the minerals contained in the rinsing water

2.1. Deposits of adhesive from the cover or from the adhesive film on the bodywork or glass

CAUTION : Recommendations for thinners index L5 : Do not leave the product acting for more than one minute. Do not apply the product on plastic components.

Dab the traces of adhesive(at "a") ; Using a soft cloth, impregnated with a diluting agent index L5.

This first step of impregnation limits wiping, which could potentially pose a risk of scratching.

After removing all the traces of adhesive, wipe the surface until it is totally dry ; Using a soft cloth.

If areas of the bodywork differ in appearance, buff the entire surface of the bodywork part concerned.

2.2. Difference in shade on a partially protected component

Buff the non-protected area (at "c") to make its shade identical to that of the area previously protected by adhesive film(at "b").

N.B. : After the buffing phase, if there is still a difference in shade, heat the part of the bodywork component concerned to between 40° and 60° ; Using an infrared drier of the "short wave" type. Buff the surface again once the component has cooled down.

The distance setting depends on the products to be dried.

For further information refer to the instructions provided by the manufacturer of the equipment used.

2.3. Stains in the paint

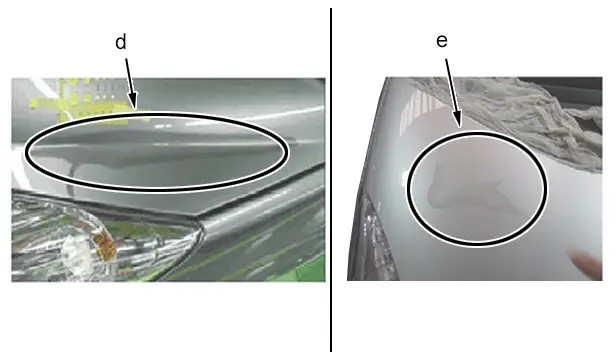

Buff the stained area(at "d", "e").

N.B. : After the buffing phase, if the stain is still present, heat the part of the bodywork component concerned to between 40° and 60° ; Using an infrared drier of the "short wave" type. Buff the surface again once the component has cooled down.

The distance setting depends on the products to be dried.

For further information refer to the instructions provided by the manufacturer of the equipment used.

If the stain is too deeply ingrained in the paint, repaint the bodywork component.

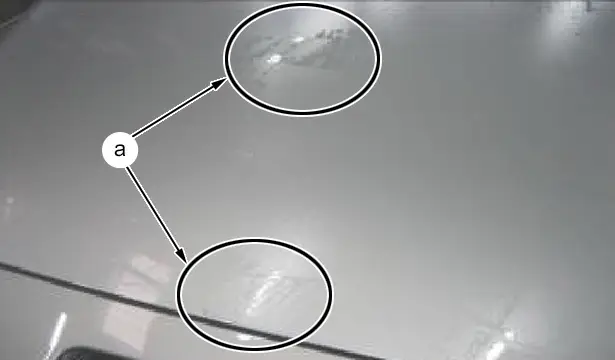

2.4. Marks on the paint

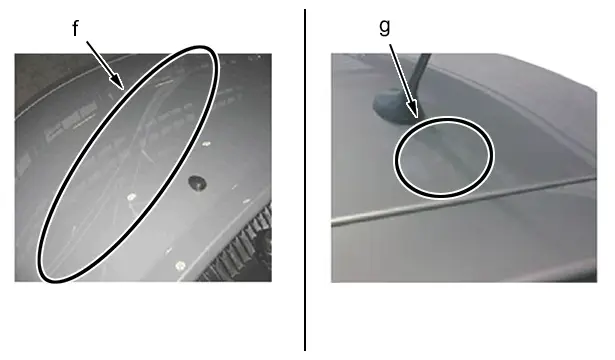

Buff the area in which the paint is marked(at "f", "g").

N.B. : After the buffing phase, if the mark is still present, heat the part of the bodywork component concerned to between 40° and 60° ; Using an infrared drier of the "short wave" type. Buff the surface again once the component has cooled down.

The distance setting depends on the products to be dried.

For further information refer to the instructions provided by the manufacturer of the equipment used.

2.5. Micro-scratches

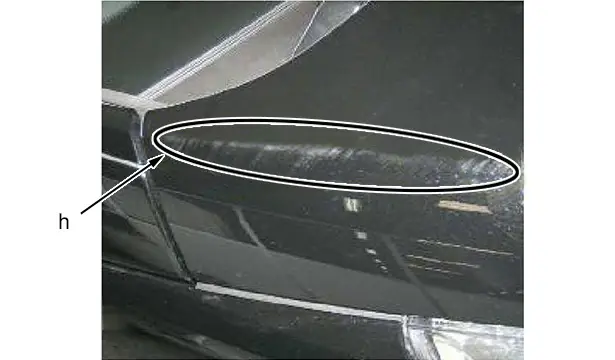

Buff the scratched area(at "h").

If the scratch remains after the buffing phase, sand the surface using ultra-fine abrasive paper index P2000 with water and buff the surface again.

If the scratch is too deep, repaint the bodywork component.

2.6. Deposits coming from the brake linings of the transport trucks

Deposits coming from the brake linings of the transport trucks are the following :

- Incrusting of corroded metallic particles on the surfaces of exterior components (Body paint, Seals, Radiator grilles, Windows, Plastic components…)

- Particles visible by the residual presence of a thin film, red or white in colour, all over the vehicle after washing

| Illustration | Comment(s) |

| Examples of faults found after washing |

| Faults on the bodywork |

| Faults on the windows |

| Faults on the plastics |

ESSENTIAL : It is compulsory to wear specific items of personal protective equipment. Particularly goggles and gloves recommended by the manufacturer of the products.

CAUTION : Ideally use the products recommended by the manufacturer

.

.

If after washing you find a residual appearance fault corresponding to any of those above, apply the repair method as instructed by the supplier.

1 - Dampen the whole of the bodywork ; Using a water spray.

2 - Dilute the product as per the supplier’s instructions.

3 - Spray the product over the whole of the bodywork.

4 - Leave it to act for 3 to 5 minutes, without allowing the product to dry (Action with a soft brush may be necessary on surfaces that are heavily affected).

5 - Rinse the vehicle with plenty of water.

6 - Apply a bodywork shampoo in order to remove any residual trace of product.

7 - Rinse the vehicle with plenty of water.

8 - Repeat the operation if necessary.

N.B. : The presence of a residual roughness to the touch without visible particles on the bodywork does not justify this treatment. This roughness lessens with each wash and finally disappears completely.

2.7. Deposits of burnt particles from overhead railway electric cables

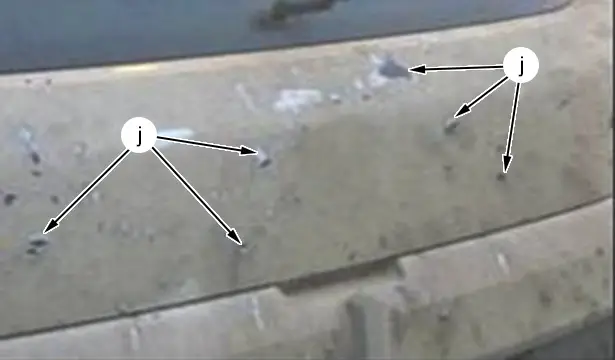

"j" Deposits of burnt particles from overhead cables.

ESSENTIAL : It is compulsory to wear specific items of personal protective equipment. Particularly goggles and gloves recommended by the manufacturer of the products.

CAUTION : Keep to the dosages as instructed by the supplier.

N.B. : The presence of a residual roughness to the touch without visible particles on the bodywork does not justify this treatment. This roughness lessens with each wash and finally disappears completely.

Clean off all traces left by these deposits, using the recommended phosphate rust-removing product and the following procedure :

- Dilute the product as per the supplier’s instructions

- Apply with a brush

- Let it act until all the stains have disappeared

- Rinse the vehicle with plenty of water

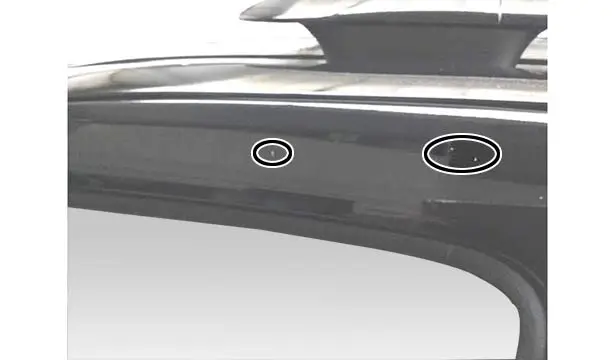

2.8. Deposits of paint particles

The consequences of paint deposits coming from fumes from the paint workshop are as follows :

- Residual presence of visible defects on the surface of exterior components on parts of the vehicle after washing (Body paint, Seals, Radiator grilles, Windows, Plastic components…)

- Residual presence of a thin film of paint on parts of the vehicle after washing

| Illustration | Comment(s) |

| Examples of faults found after washing : Faults on the bodywork |

| |

|

ESSENTIAL : It is compulsory to wear specific items of personal protective equipment. Particularly goggles and gloves recommended by the manufacturer of the products.

CAUTION : When cleaning a vehicle with a textured or matt body colour, do not use polish for touch-ups or finishing wax at the end of washing (the matt appearance may be lost resulting in a gloss appearance). Use the appropriate recommended products to maintain the original appearance of the paintwork.

CAUTION : Ideally use the products recommended by the manufacturer

.

.

If after washing you find a residual appearance fault corresponding to any of those above, apply the repair method as instructed by the supplier.

2.8.1Faults on the bodywork.

1 - Dampen the whole of the bodywork ; Using a water spray.

2 - Treat the affected area by gently sanding ; Using P6000 damp abrasive paper with an ultra-fine grain or a wet clay cloth.

3 - Dry the treated area ; Using a chamois leather.

4 - Mechanically buff the treated area ; Using a polisher and buffing product (Index L7).

5 - Wipe the vehicle ; Using a microfibre cloth.

N.B. : This treatment cannot be justified if there is a residual roughness to the touch with no visible particles on the bodywork ; Repeat steps 4 and 5.

2.8.2Faults on the windows.

1 - Clean the affected area ; With a scraper blade.

2 - Manually buff the affected area ; Using a buffing product (Index L7).

3 - Wipe the treated area ; Using a microfibre cloth.

N.B. : If there is a residual roughness to the touch with no visible particles on the affected area ; Repeat steps 2 and 3.

2.8.3Small faults on the windows.

1 - Dampen the affected area ; Using a water spray.

2 - Manually buff the affected area ; Using a buffing product (Index L7).

3 - Wipe the treated area ; Using a microfibre cloth.

N.B. : If there is a residual roughness to the touch with no visible particles on the affected area ; Repeat steps 2 and 3.

2.8.4Faults on the raw plastics.

1 - Dampen the affected area ; Using a water spray.

3 - Manually rub the area affected ; With a wash brush.

4 - Wipe the treated area ; Using a microfibre cloth.

N.B. : This treatment cannot be justified if there is a residual roughness to the touch with no visible particles on the affected area ; Repeat steps 3 and 4.

2.9. Traces left by the minerals contained in the rinsing water

CAUTION : Keep to the dosages as instructed by the supplier.

Do a final rinsing using the self-drying product recommended by the manufacturer, then leave to dry naturally without wiping.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image